1-Ton Jib Cranes for Sale: 1 Ton Jib Crane Types & Crane Specs

Explore 1-ton jib cranes for sale, including free-standing, wall-mounted, and articulating types with key specifications and practical applications.

1-Ton Jib Cranes for Sale : Types & Specifications

Jib cranes are simple yet powerful lifting devices that help you move heavy materials safely and efficiently within a limited area. Unlike large overhead cranes, they don't take up much space and can be installed in corners, along walls, or even as free-standing units. They are ideal for workplaces where frequent lifting and positioning of loads is needed without the hassle of moving an entire overhead crane system.

Capacity

A 1-ton jib crane can lift up to 2,000 pounds, which makes it perfect for light-duty applications. Think of it as the go-to solution for handling medium-sized machinery parts, pallets, or heavy tools. This capacity is enough for most workshops, maintenance areas, and small production lines.

- Standard lifting capacity: 1 ton (2,000 lbs)

- Typical load types: machinery components, toolkits, palletized goods, automotive parts

- Safety factor: Usually designed with a 125–150% safety margin for daily use

Common Applications

1-ton jib cranes are widely used across various industries. They make repetitive lifting tasks faster and reduce the risk of injury compared to manual handling. You'll often find them in:

- Manufacturing facilities – moving parts between workstations or assembly lines

- Maintenance shops – lifting engines, pumps, or heavy equipment for repair

- Warehouses – handling inventory, crates, and palletized goods

- Small production lines – assisting with material loading and unloading

These cranes can save both time and energy by allowing workers to move items without dragging or pushing heavy loads manually. They're compact, practical, and easy to operate, making them a staple in many industrial environments.

Types of 1-Ton Jib Cranes

When it comes to 1-ton jib cranes, there's no one-size-fits-all solution. Different types are designed to meet specific space, load, and workflow needs. Let's break down the main options so you can see which fits your workspace best.

Free Standing Jib Cranes 1-Ton

Free-standing jib cranes are independent structures that stand on their own, usually anchored to a concrete foundation. They're sturdy, reliable, and can handle a full 360° rotation, which makes them perfect for open areas where you need maximum flexibility.

- Mounting Options: Base plate or sleeve-insert mounted

- Typical Span: 10–20 ft, depending on the model

- Under Boom Height: Often 10–14 ft, enough for most warehouse or workshop layouts

- Example:Free Standing Jib Crane with a 20 ft span and 12 ft under boom height

These cranes are ideal for medium-sized workspaces where you want full rotation without relying on wall support. They're versatile and often used in assembly lines, maintenance shops, and areas where lifting loads in multiple directions is required.

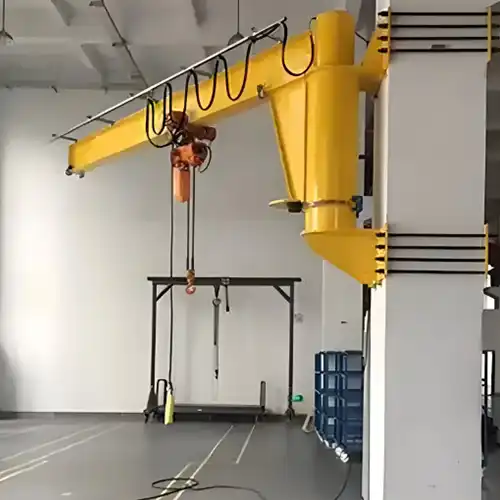

Wall-mounted jib cranes attach directly to a wall or strong column, saving valuable floor space. They typically rotate between 200° and 270°, which covers most lifting tasks along a workbench or production line.

- Ideal For: Spaces with limited floor area

- Mounting Requirements: Solid wall or reinforced column capable of supporting the load

- Span Options: Usually 10–20 ft

- Example: Gorbel Wall Cantilever I-Beam Jib Crane with a 20 ft span

These cranes are perfect if you don't have room for a free-standing model. They're commonly seen in warehouses, workshops, and small production areas where materials need to be moved along one plane rather than all around the workspace.

Portable jib cranes are designed with a wheeled base, allowing the entire crane to be moved easily between workstations. They provide 1-ton lifting capacity without the need for a fixed foundation, making them an excellent choice for flexible operations.

- Rotation: Typically 360° depending on the base design, offering full coverage in a mobile setup

- Use Case: Ideal for loading/unloading trucks, moving materials between stations, or handling tasks in temporary work areas

- Span & Height: Varies by model but generally designed for quick setup and mobility

Articulating Jib Cranes 1-Ton

Articulating jib cranes have multiple joints, allowing the boom to bend or reach around obstacles. This type is extremely handy in tight areas or when you need to lift loads under or around machinery.

- Rotation: Varies depending on the joints; can maneuver around obstacles

- Use Case: Accessing hard-to-reach spaces or loading/unloading tricky areas

- Span & Height: Highly adjustable depending on the model

These cranes are often chosen for repair shops, specialized production areas, or any workspace where obstacles prevent straight-line lifting. They're flexible and can improve workflow in areas where space is tricky.

Key Specifications of Jib Cranes

Choosing the right 1-ton jib crane isn't just about picking a model you like. You need to look closely at its specifications to make sure it fits your workspace, handles the loads you need, and works safely every day. Let's go through the key specs you should check.

Capacity

Capacity is the most critical factor. A 1-ton jib crane can lift up to 2,000 lbs, which is plenty for many light-duty tasks. But it's not just about the number—think about the types of loads you'll move regularly. Overloading a crane, even slightly, can be dangerous and shorten its lifespan.

- Standard Capacity: 1 ton (2,000 lbs)

- Typical Loads: Pallets, machine parts, tools, equipment

- Tip: Always match the crane's rated capacity to the heaviest load you'll handle.

- Example: Most 1-ton Gorbel and Spanco cranes are designed with a safety margin of 125–150%, allowing consistent use without worry.

Span

Span refers to the horizontal distance from the center of the mast or wall mount to the tip of the boom. It determines how far the crane can reach and is essential for planning your workspace layout.

- Common Sizes: 10 ft, 12 ft, 16 ft, 20 ft

- Considerations: Longer spans cover more area but may need stronger foundations or support

- Example: Spanco 1 Ton Base Mounted Jib Crane comes with a 10 ft span, ideal for workshops or assembly lines with moderate reach requirements

Height Under Boom (HUB)

HUB is the vertical clearance from the floor to the underside of the crane's boom. You need enough clearance to move tall items or stack pallets underneath safely.

- Common Heights: 10 ft, 12 ft, 14 ft

- Tip: Measure the tallest load you'll lift and add some buffer for safety

- Example: Gorbel Free Standing I-Beam Jib Crane offers a 14 ft HUB, making it suitable for most industrial workspaces

Rotation

Rotation determines how far you can swing the boom to move a load. Some cranes rotate manually, while others are motorized for smoother, easier operation.

- Manual Rotation: Operated by hand, simple and reliable

- Motorized Rotation: Uses a powered mechanism for frequent or heavy-duty lifting

- Typical Range: 200°–360°, depending on crane type and installation

- Example: Gorbel Free Standing Jib Crane rotates a full 360°, allowing complete coverage of a workstation or storage area

Foundation Requirements

Foundation requirements depend on the crane type. Free-standing models need a solid concrete base, while wall-mounted cranes rely on the strength of the supporting wall or column.

- Free Standing Cranes: Require a concrete foundation for stability

- Wall-Mounted Cranes: Must attach to reinforced walls or columns capable of supporting the load

- Example: Spanco 1 Ton Base Mounted Jib Crane requires a 5' x 5' concrete pad for secure installation

Selection Considerations

Choosing the right 1-ton jib crane is about more than just capacity or price. You need to think about your workspace, the type of loads you handle, and how often the crane will be used. Here's a practical guide to help you make the best choice.

Low Headroom jib cranes- with full cantilever and wall mounted jib crane types

Low Headroom jib cranes- freestanding column mounted jib crane types

Space Availability

Not every workspace has room for a free-standing crane. If floor space is limited, a wall-mounted crane can save a lot of room while still handling your lifting needs. Free-standing cranes require open areas and a solid foundation, so plan accordingly.

- Tip: Measure the available floor area before choosing a crane type

- Best For Limited Space: Wall-mounted or mast cranes

- Example: A small maintenance shop with narrow aisles often works best with a wall-mounted jib crane

Load Requirements

Always match the crane to the heaviest load you'll lift. Even a 1-ton crane can struggle if loads frequently approach its limit. Consider the typical weight of your items plus a small safety buffer to avoid overloading.

- Tip: Keep a 10–20% margin below the rated capacity for safety

- Common Loads: Pallets, engine blocks, machinery parts

- Example: For moving engine components, a 1-ton crane provides enough lifting power without strain

Foundation Constraints

Some cranes need substantial foundations, while others can be installed with minimal floor work. Free-standing cranes typically require a concrete pad, whereas mast or articulating cranes can work with smaller or less invasive setups.

- Tip: Check your floor's load-bearing capacity before installation

- Best For Limited Foundation Work: Mast type or articulating cranes

- Example: A workshop that cannot pour a large concrete pad may benefit from a mast-mounted jib crane

Operational Needs

Think about how often and how quickly the crane will be used. Manual rotation works well for occasional lifting, but motorized rotation is much easier for frequent or repetitive tasks. It can reduce fatigue and improve workflow efficiency.

- Tip: High-use areas may benefit from motorized or assisted rotation

- Manual vs Motorized: Manual is simple and cost-effective; motorized is easier for heavy or repetitive loads

- Example: Assembly lines that move parts continuously will see time savings with motorized rotation

By considering space, load, foundation, and operational needs, you can choose a jib crane that works safely and efficiently in your specific environment. Making the right selection upfront saves money, time, and potential safety issues later.

Conclusion

Choosing the right 1-ton jib crane comes down to understanding your workspace and the work you need to do. Think about the available floor space, the weight and type of loads, and the foundation you can provide.

Knowing the different types—free-standing, wall-mounted, mast, or articulating—helps you match the crane to your workflow. Pay attention to key specifications like span, height under boom, rotation, and foundation requirements. These details make a big difference in safety, efficiency, and long-term performance.

In the end, a carefully chosen jib crane doesn't just lift loads—it makes daily operations smoother, reduces strain on your team, and keeps your workplace running safely. Take the time to assess your needs and pick the model that fits best; it's a small investment that pays off every day.